Shot Peening of Coil Springs

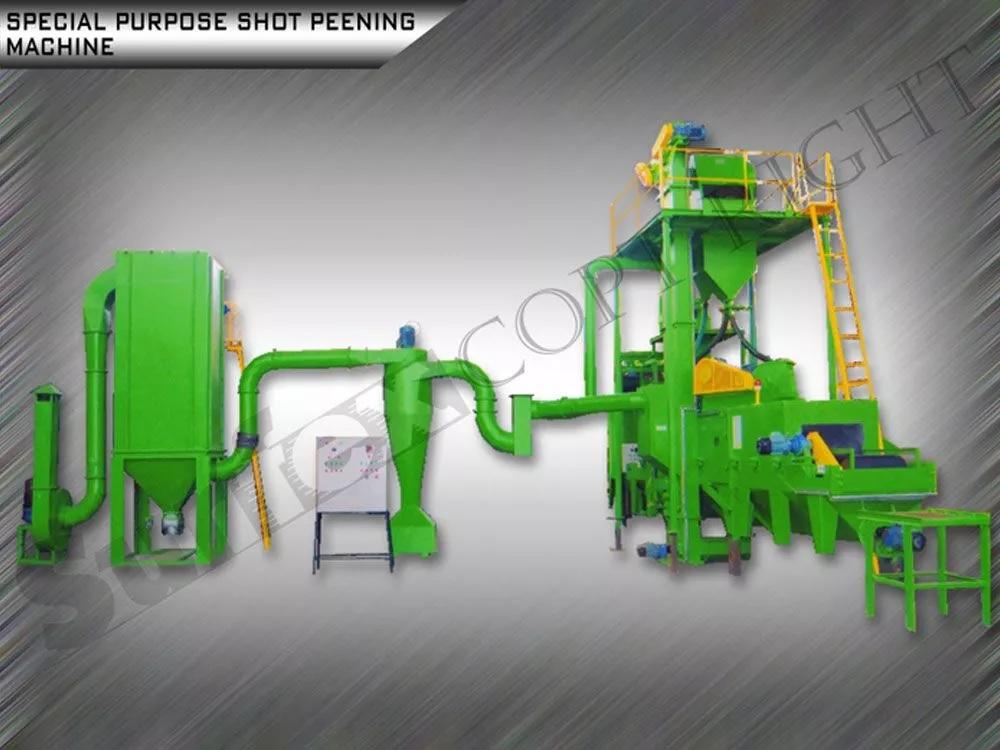

SURFEX® designs and manufactures the Shot Peening Machine for Coil Springs.

Coil springs to be shot peened will be placed on the inward side of the roller conveyor. The Coil Springs are transferred into the peening chamber, where they are shot peened. On the roller conveyor, the coil springs are rotating as well as moving in the forward direction automatically. Suitable numbers of “Surfex” advanced blast wheel stations are located strategically at the top side of the peening chamber, which fires the peening media on the coil springs. The peened material moves forward & enters the outlet tunnel for job unloading.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the peening chamber.

Shot Peening of Top Side of Leaf Springs

SURFEX® designs and manufactures the Shot Peening Machine for Leaf Springs.

Leaf springs to be shot peened will be placed on the inward side of the rubber belt conveyor (or chain conveyor). The Leaf Springs are passed through an inward tunnel of the shot peening machine and enter the peening chamber, where they are shot peened from the top side. Suitable numbers of “Surfex” advanced blast wheel stations are located strategically at the top side of the peening chamber, which fires the peening media on the leaf springs. The peened material moves forward & enters the outlet tunnel, and further moves to the conveyor at the outlet side for job unloading.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the peening chamber.