Cleaning, Heat Scale and Rust Removal

Manual Operation.

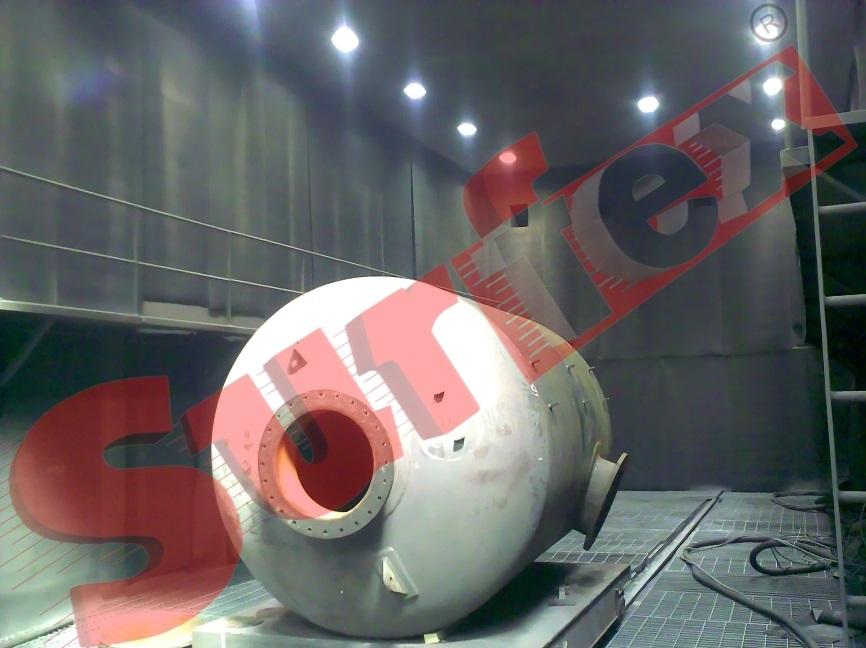

SURFEX® designs and manufactures the Blast Room with Scrapper Type Media Recovery System for Manual Blasting a wide range of components (Castings / Fabricated / Forgings / Structural Cleaning / etc.).

The job to be blasted will be first taken inside the blast room, and the blasting operation is carried out by the operator manually. Used blasting abrasive media falls into the scrapper units through floor gratings, from where it is conveyed by longitudinal scrappers to a cross screw conveyor. The cross screw conveyor conveys the abrasive media into the boot of bucket elevator. The bucket elevator lifts the media and pours it into media separation unit, from where the reusable blasting abrasive media goes into the Portable Abrasive Blaster and blasting abrasive media is recycled through the blast nozzle.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast room.

Cleaning / Heat Scale and Rust Removal

Manual Operation

SURFEX® designs and manufactures the Blast Room with Screw Conveyor Type Media Recovery System for Manual Blasting a wide range of components (Castings / Fabricated / Forgings / Structural Cleaning / etc.).

The job to be blasted will be first taken inside the blast room, and the blasting operation is carried out by the operator manually. Used blasting abrasive media falls into the screw conveyor units through floor gratings, from where it is conveyed by longitudinal screw conveyors to a cross screw conveyor. The cross screw conveyor conveys the abrasive media into the boot of bucket elevator. The bucket elevator lifts the media and pours it into media separation unit, from where the reusable blasting abrasive media goes into the Portable Abrasive Blaster and blasting abrasive media is recycled through the blast nozzle.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast room.

Cleaning / Heat Scale and Rust Removal

Manual Operation

SURFEX® designs and manufactures the Blast Room with Mini Hopper Type Media Recovery System for Manual Blasting a wide range of components (Castings / Fabricated / Forgings / Structural Cleaning / etc.).

This type of media recovery system is specially used where the blasting abrasive media is very fine like Glass Bead, Alumina Oxide, etc.

The job to be blasted will be first taken inside the blast room, and the blasting operation is carried out by the operator manually. Used blasting abrasive media falls into the mini hopper system through floor gratings, from where it is sucked inside the reclaimer unit by the suction draft created by the vacuums suction of the exhaust blower. The cyclonic action inside the reclaimer unit separates the dust and abrasive. The separated abrasive passed to screen, where coarse particles and debris are separated. The usable abrasive gets stored in storage tank and from where the abrasive will go into the Blast Generator (Pressure Vessel). The abrasive is recycled through the blast nozzle.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast room.