Roll Etching Machine (or Roll Blasting or Roll Texturing Machine)

Automatic Operation

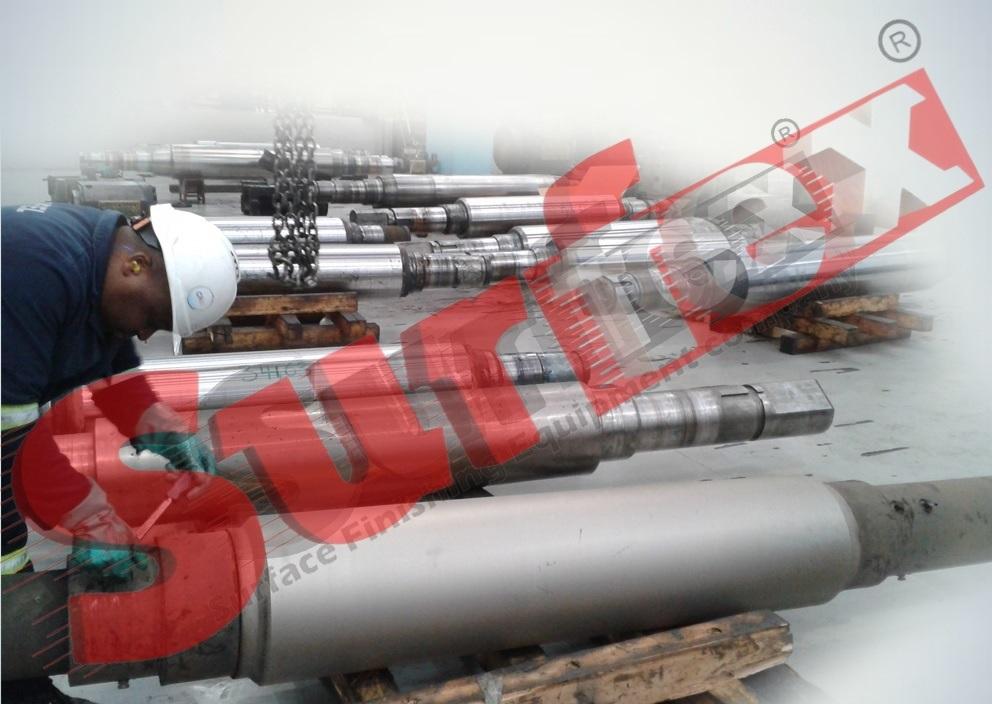

SURFEX® designs and manufactures the Air Operated Roll Etching (or Roll Blasting / Roll Texturing) for a Rolls used in Rolling Mills.

The machine will be based on Pressure Principle.

The machine will consist of blast cabinet, job support and rotating station with work car, horizontal nozzle reciprocating arrangement, reclaimer unit, storage tank, blast generator and dust collector system.

A fixed rotating station is there on which the rolls are placed. The rotating station will have 2 No’s of rollers which are duly rubber lined, which rotates the component.

The Roll will rotate on its axis and the blast nozzle will move forward & backward (with the help of nozzle reciprocation arrangement) and clean the Roll uniformly from outer periphery.

The abrasive stored in the bottom storage hopper will be sucked inside the reclaimer unit by the suction draft created by the vacuums suction of the exhaust blower. The cyclonic action inside the reclaimer separates the dust and abrasive. The separated abrasive passed gets stored in abrasive storage tank. From abrasive storage tank, the abrasive will go into the blast generator (pressure vessel) for the reuse purpose. From the pressure vessel, the blasting abrasive media is carried away by the compressed air to the blast nozzle for roll basting.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.

When it comes to advanced surface treatment and texturing technology, roll etching machine manufacturers like Sfecindia are setting new standards in industrial excellence. A roll etching machine is primarily used for creating uniform textures, designs, or patterns on metal rolls, which are crucial in applications like printing, embossing, and surface preparation. As one of the most trusted roll etching machine manufacturers in India, Sfecindia delivers precision, innovation, and unmatched quality in every product they offer. Their machines are engineered for high efficiency, automation compatibility, and low maintenance, making them a preferred choice across multiple heavy industries.

What is a Roll Etching Machine?

A roll etching machine is used to engrave or texture cylindrical rolls by chemical or electrochemical methods. This machine is vital in manufacturing processes where surface texture plays a crucial role in end-product quality.

Sfecindia stands out in the market not only for its cutting-edge technology but also for its client-centric approach. The company’s machines are built with robust materials to ensure long-term performance and resistance to corrosion, wear, and mechanical stress. These attributes make Sfecindia one of the leading roll etching machine manufacturers with a reputation for reliable and durable solutions.

Key Features of Sfecindia Roll Etching Machines:

High Precision Control: Their machines allow micro-adjustments to ensure uniform etching depth and pattern accuracy.

User-Friendly Interface: Operators can easily set up, monitor, and control the etching process using intuitive digital interfaces.

Custom Design Capabilities: Sfecindia offers customization to meet specific industry needs such as roll size, pattern type, and etching method.

Safety & Compliance: Machines are designed in accordance with industrial safety standards and come with multiple fail-safe mechanisms.

Energy Efficiency: Designed to consume less power while delivering high output rates, helping reduce operational costs.

Why Choose Roll Etching Machine Manufacturers Like Sfecindia?

They offer tailor-made solutions, provide long-term service support, and ensure every machine is tested for performance and durability before delivery.

What further sets Sfecindia apart from other roll etching machine manufacturers in India is their commitment to research and development. The company constantly works on enhancing its technology to provide more eco-friendly, faster, and smarter solutions. Clients from automotive, printing, steel, and other sectors have benefited from their expertise and consistent after-sales support.

As industries evolve, the need for advanced texturing and precision becomes non-negotiable. This is where a trusted name like Sfecindia plays a critical role. Their focus on customer satisfaction, along with technical excellence, makes them a top contender among roll etching machine manufacturers not only in India but globally.

Sfecindia – Precision, Performance, Perfection in Roll Etching Machines.

If you are looking for a high-quality roll etching machine, investing in a solution from Sfecindia ensures you are backed by a legacy of engineering excellence and industrial trust.

India has emerged as a significant hub for industrial machinery, and Roll Etching Machine Manufacturers in India are gaining global recognition for delivering precision and durability. Among these manufacturers, Sfecindia stands out as a pioneer, offering advanced solutions for surface treatment through roll etching technology. Roll etching machines are essential in industries like printing, steel, packaging, and textiles, where creating textured or patterned surfaces on metal rolls is crucial for product quality and performance.

Sfecindia, one of the most reliable roll etching machine manufacturers in India, designs machines that are built for high efficiency, corrosion resistance, and long-lasting performance. These machines use advanced electrochemical or chemical etching processes to ensure uniform texture across cylindrical rolls. With features like digital control panels, automated process flow, and customizable configurations, Sfecindia’s machines are engineered to meet diverse industrial requirements.

In the modern industrial landscape, precision and surface quality play a crucial role in manufacturing processes. This is where roll texturing machine manufacturers like Sfecindia make a significant impact. Roll texturing machines are designed to create controlled surface patterns on metal rolls, improving functionality in applications such as printing, embossing, laminating, and coating. As one of the most trusted roll texturing machine manufacturers in India, Sfecindia offers advanced and high-performance machines tailored to meet the diverse needs of today’s industries.

Sfecindia’s roll texturing machines are known for their accuracy, automation, and durability. These machines use techniques like laser, electro-discharge, or chemical texturing to create fine and repeatable surface patterns on cylindrical rolls. These textured rolls are then used in various industries including automotive, packaging, paper, and steel, where surface finish and roll grip are essential. Sfecindia stands out as a leader among roll texturing machine manufacturers by offering innovative designs and complete technical support throughout the project lifecycle.

“Roll texturing machines are used to apply precise surface textures on cylindrical metal rolls to enhance grip, reduce slippage, or improve coating application in various industries.”

What sets Sfecindia apart from other roll texturing machine manufacturers in India is their dedication to quality, customization, and technological advancement. Their machines are equipped with digital interfaces for easy operation, automated controls for consistent results, and safety features to ensure operator protection. Whether you need fine textures for high-speed printing or coarse finishes for industrial laminations, Sfecindia delivers precision-engineered solutions that exceed expectations.

Moreover, Sfecindia places a strong emphasis on energy efficiency and environmental compliance, making them a preferred name in the sustainable manufacturing segment. They work closely with clients to understand specific needs and provide roll texturing machines that align with production goals and international standards.

For businesses seeking reliable, high-performance texturing equipment, Sfecindia is a name that guarantees trust, technology, and total satisfaction. As leading roll texturing machine manufacturers, they continue to set benchmarks in the Indian market and beyond. With a combination of engineering excellence and customer-centric innovation, Sfecindia ensures your roll surface treatment needs are met with precision and professionalism.