Painting (or Coating)

Manual / Automatic Operation

1. Semi-Down Draft Type Paint Spray Booth

2. Down Draft Type Paint Spray Booth

3. Water Curtain Type Paint Spray Booth

Equipment Description:

SURFEX® designs and manufactures the Paint Spray Booth for Manual / Automatic Panting.

1. Semi- Down Draft Type Paint Spray Booth System:-

The Semi-Down Draft Type Paint Spray Booth is suitable for any type of Airless and Electrostatic Painting. The system consists of Painting Booth Enclosure, Air Intake Filters, Filter Channels for Paint Trap Filters, Air Exhaust System, outlet duct, and canopy, etc. The fresh air enters the system from the top of the booth, passing through intake filters. This allows air to flow downward, thereby washing the operator and the job for better visibility to the operator. Simultaneously, the exhaust air system sucks the suspended paint particles and fumes from the booth. These suspended paint particles get trapped in the filter channels, which are provided on the hoods. These hoods with paint trap filters are provided at either side of the job along the length of the booth.

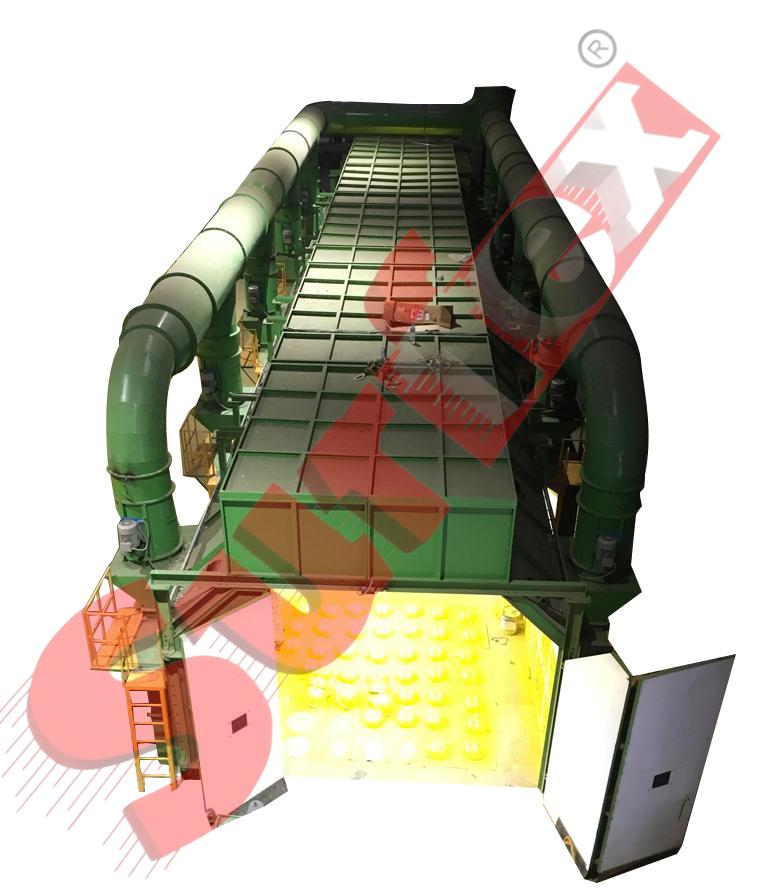

2. Down Draft Type Paint Spray Booth System:-

The Down Draft Type Paint Spray Booth is suitable for any type of Airless and Electrostatic Painting. The system consists of Painting Booth Enclosure, Air Intake Filters, Filter Channels for Paint Trap, Air Exhaust System, outlet duct, and canopy, etc. The fresh air enters the system from the top of the booth, passing through intake filters. This allows air to flow downward, thereby washing the operator and the job for better visibility to the operator. Simultaneously, the exhaust air system sucks the suspended paint particles and fumes from the booth. These suspended paint particles gets trapped in the channels which are provided with paint trap filters with gratings on the floor of the Paint Booth.

3. Water Curtain Type Paint Spray Booth System:-

The Water Screen Type Paint Spray Booth is suitable for any type of Airless and Electrostatic painting. The system consists of Painting Booth Enclosure, Water Tank for Trapping Paint Fumes, Baffle Chamber and Air Exhaust System. The fresh air enters the system from the front side of the booth; this allows air to flow vertically downwards towards the rear wall, thereby washing the operator and the job for better visibility to the operator. Simultaneously, the exhaust air system sucks the suspended paint particles and fumes from the booth. These suspended paint particles get trapped in the water screen of the chamber and then get collected inside the water pit, from where it is sucked while passing through the baffle plate, which will trap the paint fumes, and only clean air is released to the atmosphere.