A CNC Shot Peening Machine is a highly advanced and precise surface treatment solution designed to enhance the durability, strength, and fatigue resistance of metal components used across various industries. sfecindia, a leading name in surface preparation technology, specializes in manufacturing high-performance CNC Shot Peening Machines that meet international standards and deliver unmatched reliability. These machines are widely used in aerospace, automotive, marine, defense, and heavy engineering industries where component strength, crack resistance, and long-term performance are crucial.

The CNC Shot Peening Machine offered by sfecindia is equipped with cutting-edge automation and computer numerical control systems, allowing for precise control of peening intensity, coverage, and shot flow rate. This ensures uniform treatment on every component surface, minimizing the risk of stress corrosion cracking and enhancing fatigue life significantly. Our CNC Peening Machine is designed to provide consistent and repeatable results, which are essential in industries where safety and performance cannot be compromised.

One of the primary advantages of using a CNC Peening Machine is its ability to control shot velocity, angle, and exposure time with exceptional accuracy. This level of precision makes it suitable for complex and delicate components such as turbine blades, gears, automotive springs, crankshafts, and aerospace landing gear parts. With sfecindia’s CNC technology, the process is automated, eliminating human error and ensuring maximum efficiency with minimal wastage of resources.

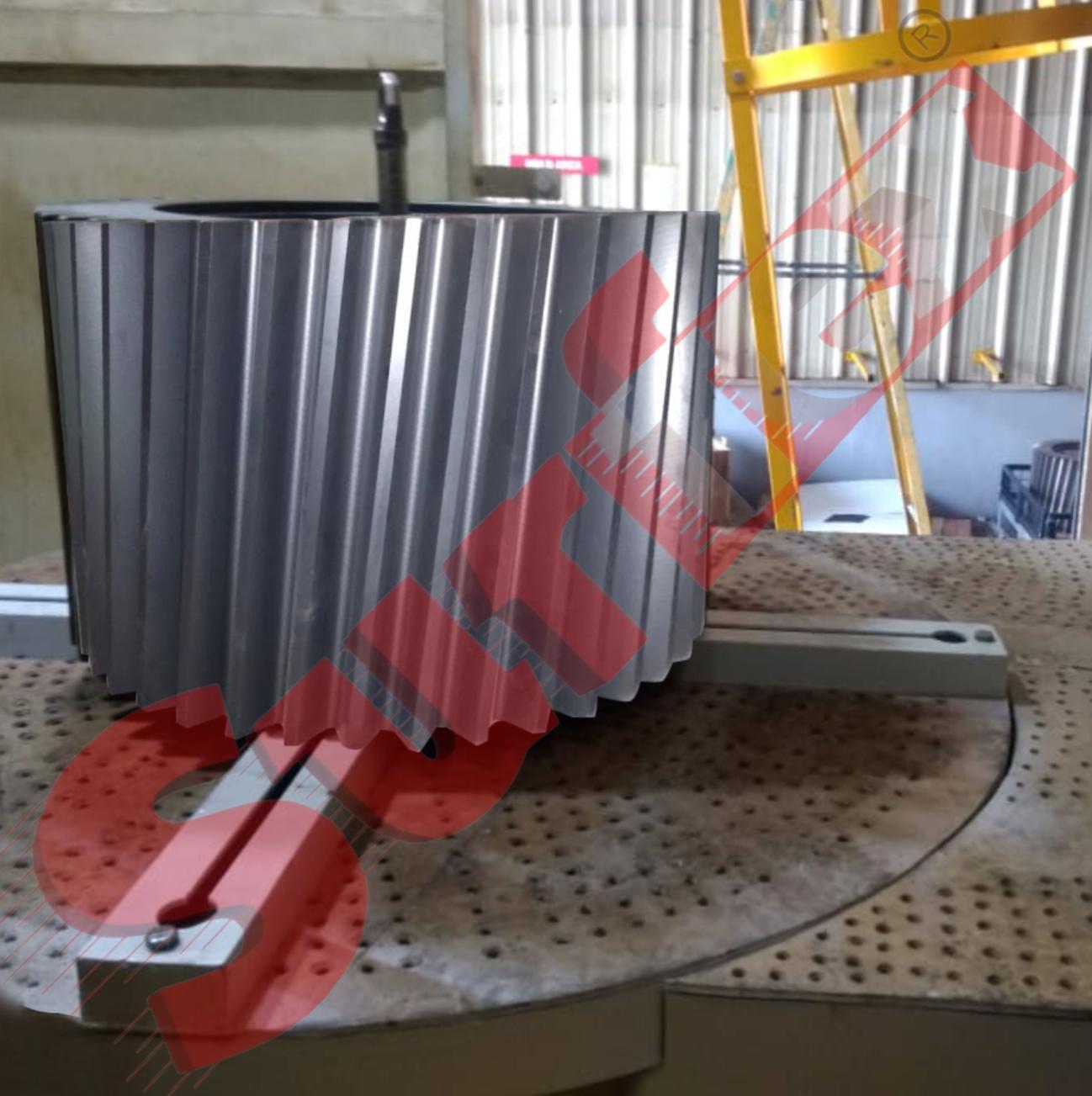

Shot Peening of Gears and Shafts

SURFEX® designs and manufactures the CNC Shot Peening Machine for Gears and Shafts. To generate the controlled compressive stress to the surface (near – surface region) and to enhance the surface properties (increase the fatigue strength), the job surface will be pounded by spherical peening media to create small indentation, which increases the life of components.

Controlled Shot Peening is regularly being specified by the automotive industry to enhance component service life (by better fatigue performance). It is a cold working process in which the surface of the job (being processed) is bombarded (or pouned) with spherical peening media. Each piece of shot striking (or pounding) the surface of the job acts as a minuscule peening hammer, deforming the job surface and causing a small indentation. The overlapping indentations develop a thin layer of metal under residual compressive stress at or near the surface. Since nearly all the fatigue and stress corrosion failures start at the surface of a job, the compressive stresses induced by shot peening can considerably increase component service life (by better fatigue performance) and move the job into a higher cycle fatigue regime.

Process consistency in the shot peening process is vital, and the “SURFEX” machines are custom designed to control all the critical variables to suit the applications.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the peening chamber.

Our machines are manufactured according to strict quality standards to meet industry demands. The standard features include:

To cater to specific industry requirements, sfecindia provides customization options with advanced features, such as:

The CNC Shot Peening Machine by sfecindia ensures improved residual compressive stress on components, reducing the chances of fatigue failure and extending their service life. The process is environmentally friendly, cost-effective, and compatible with a wide range of metallic materials. With our CNC Peening Machine, industries can achieve consistent part quality, reduced maintenance costs, and enhanced reliability of critical components.

sfecindia stands as a trusted manufacturer of CNC peening solutions in India, offering both standard and custom-designed machines to meet client-specific needs. Our focus on innovation, durability, and precision engineering has made us a preferred choice for companies seeking high-performance CNC Shot Peening Machines for advanced surface enhancement applications.