Cleaning / Heat Scale Removal / High Roughness Applications

Automatic Operation

1. Air Operated Roller Conveyor Type Shot Blasting Machine

2. Air Operated Rubber Belt Conveyor Type Shot Blasting Machine

SURFEX® designs and manufactures the Air Operated Conveyor Type Shot Blasting Machine (Continuous Type) for a wide range of components (Castings / Components of Automobile Industry / Aluminum Profiles / Bake Shoe / Clutch Plates / Ceramic Components / etc.).

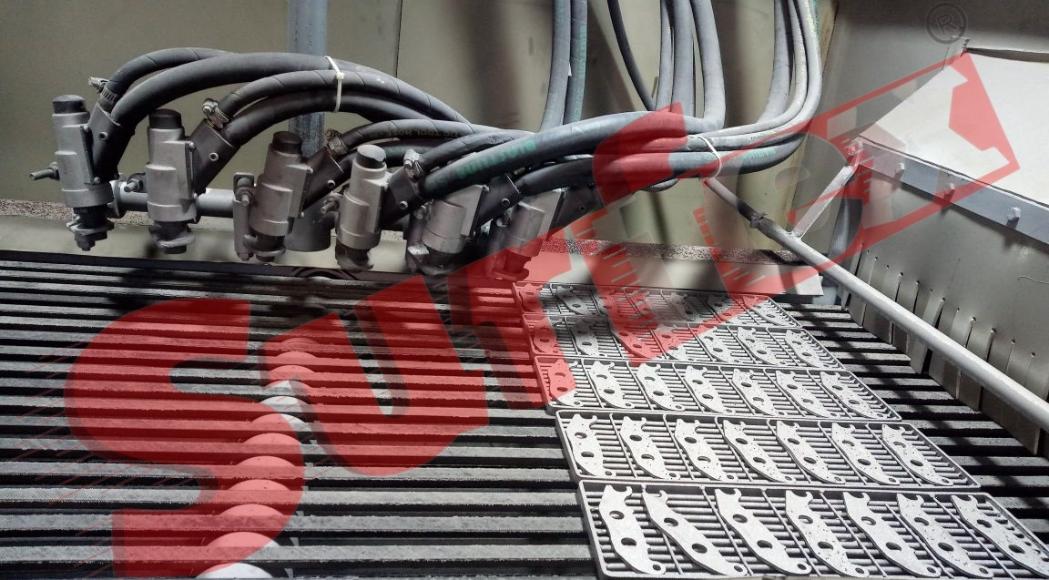

The machine consists of Blast Cabinet Conveyor Arrangement, Suitable No. of Blast Nozzles (or Suction Blast Guns), Nozzle Reciprocation Arrangement (Single or Dual- as required), Abrasive Recovery Unit and Dust Collector Unit.

The jobs are loaded on the inward side of the roller conveyor arrangement. The jobs are passed through an inward tunnel of the shot blasting machine and enter the blasting chamber for blasting purpose. Suitable number blasting nozzles are located as required (at top and bottom position from jobs), which fires blasting abrasive media on the jobs. The blasted jobs are moves forward, & enter the outlet tunnel, and further moves to the conveyor at the outlet side for job unloading.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.