Cleaning / Heat Scale Removal

Batch Operation

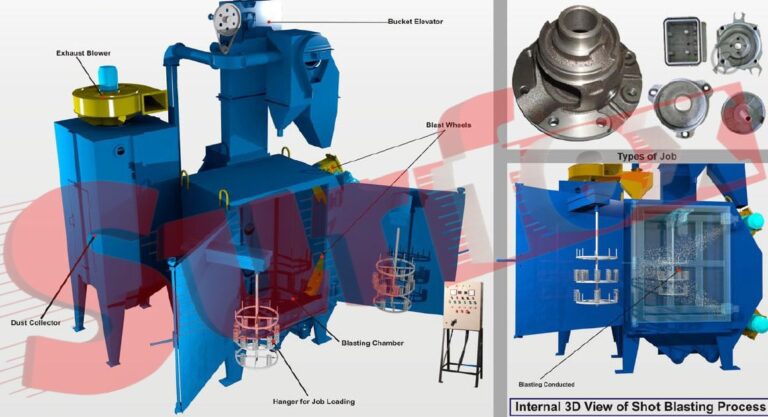

SURFEX® designs and manufactures the Door Hanger Type Shot Blasting Machine for a wide range of components (Castings / Fabricated / Forging / Aluminum Die Castings / etc.)

The door of the machine is opened and components are loaded on to the hanger (mounted on the door itself). The door is closed and the blast wheel units are operated. 2 No’s of Blast wheel stations are located strategically around the cabinet, which fires blasting abrasive media on the rotating hanger loaded with jobs. After the blast cleaning cycle is over, the blast wheel is shut-off and door is opened for unloading of components.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.

Cleaning / Heat Scale and Rust Removal.

Batch Operation

SURFEX® designs and manufactures the Y- Conveyor Type Spinner Hanger Shot Blasting Machine for a wide range of components (Castings / Fabricated / Forging / Aluminum Die Castings / Agriculture Components / etc.).

The machine consists of Total 2 No’s of Stations. The Trolleys (2 Set – one on each station) are mounted on the overhead Y- conveyor system to hold the jobs. The jobs to be shot blasted are loaded on these stations and one by one moved inside the blasting chamber for blasting purpose automatically. Suitable number of blast wheel stations are located (at one side of cabinet) strategically around the cabinet, which fires blasting abrasive media on the rotating job/ hanger that contain jobs. After the blast cleaning cycle is over, the blast wheel is shut off and trolley moves out automatically for unloading of component and the process is repeated.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.

Cleaning / Heat Scale Removal

Batch Operation

SURFEX® designs and manufactures the I-Conveyor Type Spinner Hanger Shot Blasting Machine for a wide range of components (Castings / Fabricated / Forging / Aluminum Die Castings / Agriculture Components / etc.) and for Structure Cleaning.

The machine consists of Total 1 No. of Station. The Trolley (1 Set – one on each station) is mounted on the overhead I- conveyor system to hold the jobs. The jobs to be shot blasted are loaded on these stations and moved inside the blasting chamber for blasting purpose automatically. Suitable numbers of blast wheel stations are located strategically around the cabinet, which fires blasting abrasive media on the rotating job/ hanger that contain jobs. After the blast cleaning cycle is over, the blast wheel is shut off and trolley moves out automatically for unloading of component and the process is repeated.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.

Cleaning / Heat Scale and Rust Removal.

Continuous Operation

SURFEX® designs and manufactures the Overhead Close Loop Conveyor Type Spinner Hanger Shot Blasting Machine (with Chain Conveyor) for a wide range of components (Castings / Fabricated / Forging / Aluminum Die Castings / Agriculture Components / etc.).

The machine consists of multiple sets (as required) of job conveying stations to hold the jobs. The jobs to be shot blasted are loaded on these stations and taken one by one inside the blasting chamber for blasting purpose automatically. Suitable numbers of blast wheel stations are located strategically around the cabinet, which fires blasting abrasive media on the rotating job/ hanger that contain jobs. After the blast cleaning cycle is over, the blast wheel is shut off and trolley moves out automatically for unloading of component and the process is repeated.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.

Cleaning / Heat Scale Removal

Continuous Operation

SURFEX® designs and manufactures the Overhead Close Loop Conveyor Type Pass Through Shot Blasting Machine (with Chain Conveyor) for a wide range of components (Castings / Fabricated / Forging / Aluminum Die Castings / Agriculture Components / etc.) and for Structural Cleaning.

The machine consists of multiple sets (as required) of job conveying stations to hold the jobs. The jobs to be shot blasted are loaded on these stations and taken one after another (with suitable gap) inside the blasting chamber (on continuous basis) for blasting purpose automatically. Suitable numbers of blast wheel stations (suitable number on one side and also on opposite side for continuous pass through shot blasting operation) are located strategically around the cabinet, which fires blasting abrasive media on the jobs. After the blast cycle is over, the job conveying station moves (with blasted job) out automatically for unloading of component and the process is repeated continuously.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.

Cleaning / Heat Scale and Rust Removal.

Continuous Operation

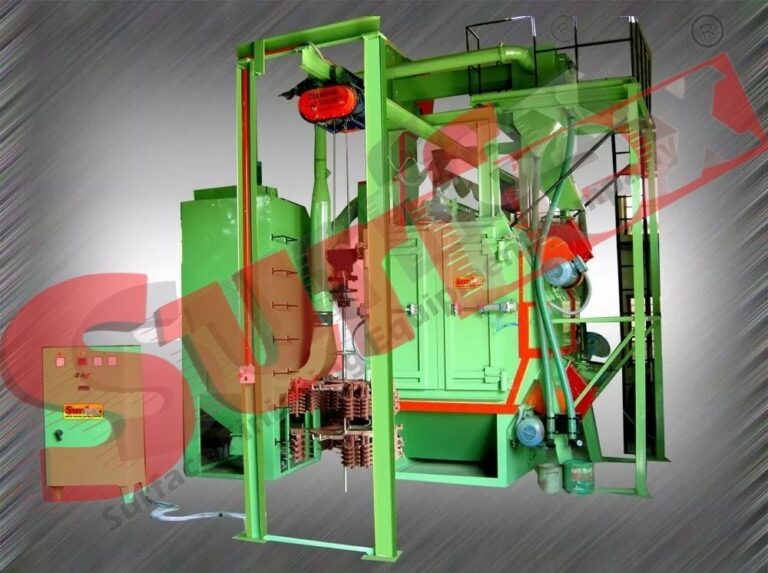

SURFEX® designs and manufactures the Indexing Hanger Type Shot Blasting Machine for a wide range of components (Castings / Forging / Aluminum Die Castings / etc.).

The machine consists of suitable number job stations (2 No’s / 4 No’s) with indexing hanger. The job is load (placed) manually on the job fixture (hangers) of the respective station of the main indexing turn table by the operator at the loading / un-loading station. Then the station (with loaded hanger) is indexed into the blasting chamber for shot blasting purpose. Suitable numbers of blast wheel stations are located strategically around the cabinet, which fires abrasives on the rotating jobs. After the blast cycle is over, the station (with blasted jobs) is indexed for unloading and simultaneously another station containing the new jobs index into the blasting chamber thus makes the process continuous.

When one station (with jobs) is under the blasting operation in blasting chamber, simultaneously at loading/ un-loading station the operator will un-load the blasted jobs and load the new jobs manually.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.