Cleaning / Heat Scale and Rust Removal

Automatic Operation

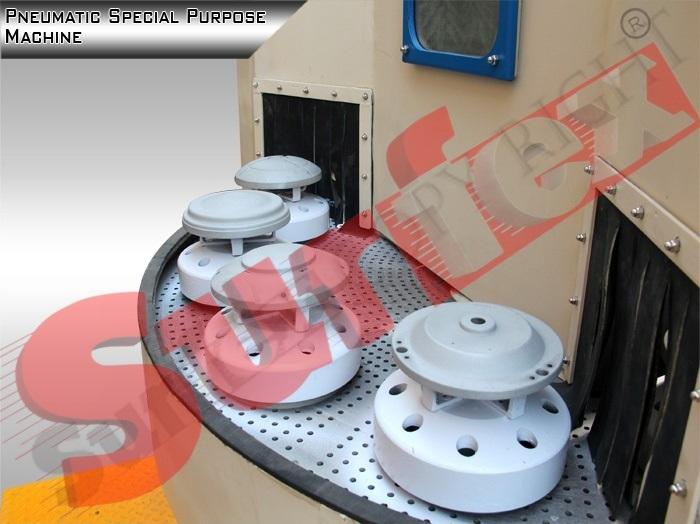

SURFEX® designs and manufactures the Air Operated Indexing Table Type Shot Blasting Machine for a wide range of components (Components of Automobile Industry / Components of Aerospace Industry / Castings / Forgings / etc.).

The machine will be based on either Suction Principle or Pressure Principle. In this machine, Main Turn table having suitable number of Satellite Stations (4 / 6 / 8 / 12 or as suitable) will be provided. The components that are to be shot blasted are load on these satellite stations at loading/ unloading stations.

The machine is equipped with suitable number of Suction Blast Guns (in case of suction principle based machines) or suitable number of Blast Nozzles (in case of pressure principle based machines) and these suction blast guns / blast nozzles are mounted on Motorized Nozzle Reciprocation Arrangement. Blast Nozzles or Suction Blast Guns will fire the abrasive media on the components placed on satellite station & shot blast the components homogeneously all around.

After shot blasting the main indexing turn table will index at pre- set angle and another suitable number of satellite stations having new components will come inside the blasting chamber and thus making the process continuous.

1. In case of Suction Principle Based Machine:

The abrasive stored in the bottom storage hopper will be sucked inside the reclaimer unit by the suction draft created by the vacuums suction of the exhaust blower. The cyclonic action inside the reclaimer separates the dust and abrasive. The separated abrasive passed through vibrating screen, where coarse particles and debris are separated and the usable abrasive gets stored in abrasive storage tank. From the storage tank the abrasive will be distributed to the system for recycling.

2. In case of Pressure Principle Based Machine:

The fired media is collected in bottom hopper of the cabinet from where it will fall down into the motorized screw conveyor unit. The motorized screw unit conveys the abrasive media to the boot of bucket elevator unit. The bucket elevator unit lifts the media and feeds the media to vibratory sieve classifier unit (optional). The classifier contains a vibrating screen in which the coarse/small size shots are separated. These are discharged through separate spouts. Usable sized shots are then transfer to the abrasive storage tank.

From abrasive storage tank, the abrasive will go into the blast generator (pressure vessel). From the pressure vessel, the blasting abrasive media is carried away by compressed air to the blast nozzle for basting.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.