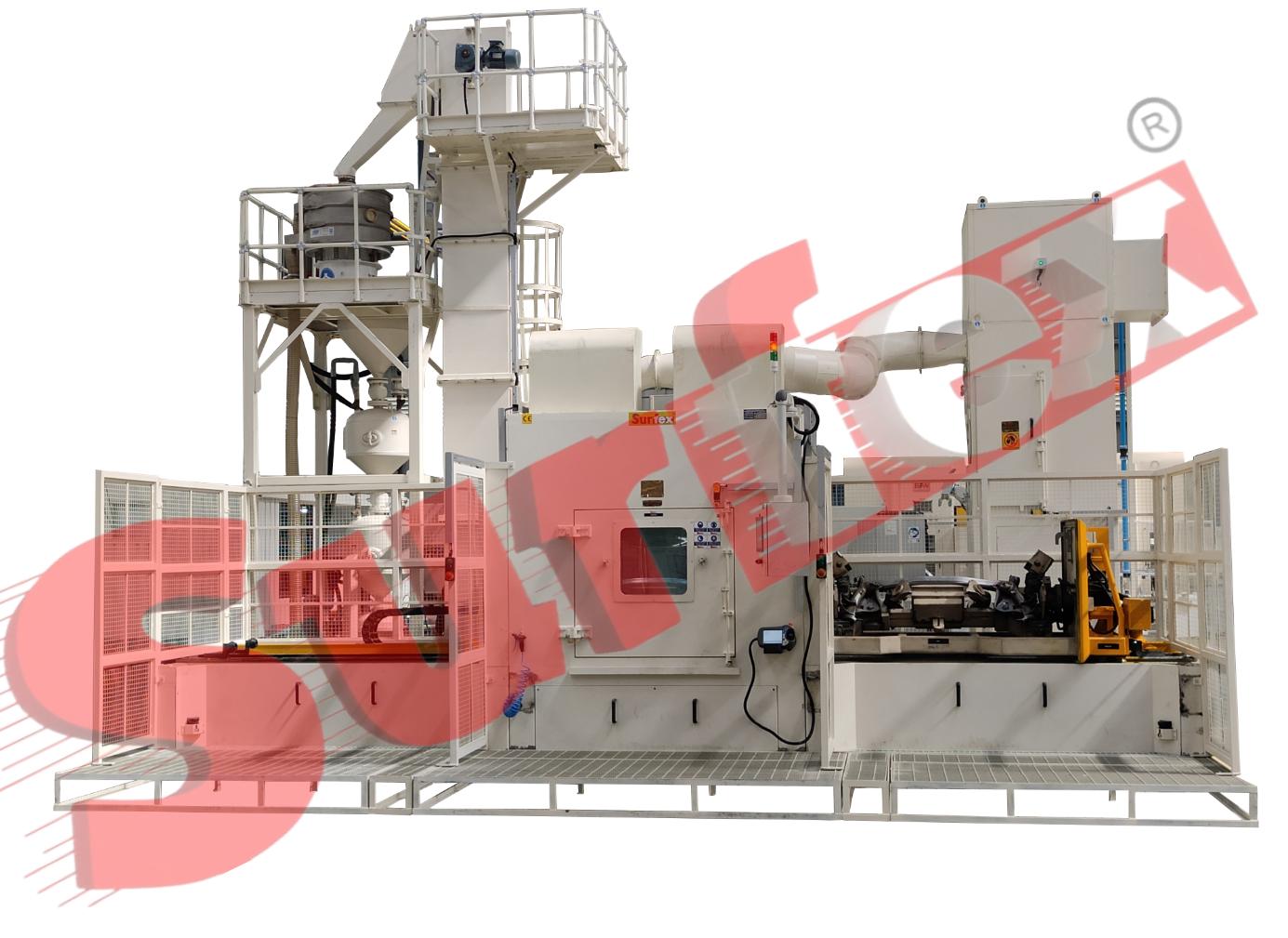

Shot Peening

SURFEX® designs and manufactures Robotic Shot Peening M/c for Automobile Industry. To generate the controlled compressive stress to the surface (near – surface region) and to enhance the surface properties (increase the fatigue strength), the job surface will be pounded by spherical peening media to create small indentation, which increases the life of components.

Controlled Shot Peening is regularly being specified by the aerospace industry to enhance component service life (by better fatigue performance). It is a cold working process in which the surface of the job (being processed) is bombarded (or pouned) with spherical peening media. Each piece of shot striking (or pounding) the surface of the job acts as a minuscule peening hammer, deforming the job surface and causing a small indentation. The overlapping indentations develop a thin layer of metal under residual compressive stress at or near the surface. Since nearly all the fatigue and stress corrosion failures start at the surface of a job, the compressive stresses induced by shot peening can considerably increase component service life (by better fatigue performance) and move the job into a higher cycle fatigue regime.

Process consistency in the shot peening process is vital, and the “SURFEX” machines are custom designed to control all the critical variables to suit the applications.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the peening chamber.