Cleaning / Heat Scale Removal

Batch Operation

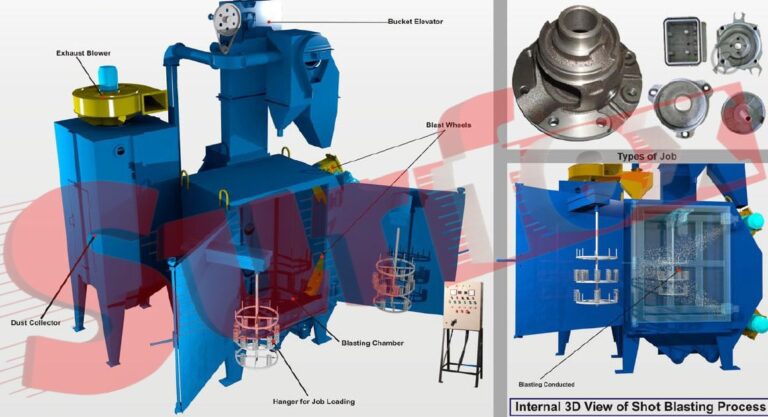

SURFEX® designs and manufactures the Door Hanger Type Shot Blasting Machine for a wide range of components (Castings / Fabricated / Forging / Aluminum Die Castings / etc.)

The Y Hanger Type Shot Blasting Machine is one of the most advanced and reliable surface preparation solutions used in different industries to clean, polish, and strengthen metal components. This machine is specially designed for heavy-duty applications where parts need uniform blasting without damage. At sfecindia, we focus on delivering high-quality machines that are built to handle complex blasting needs with maximum efficiency. The Y Hanger Type Shot Blasting Machine is widely used in industries like automotive, aerospace, steel, and construction, where components such as engine parts, castings, and metal structures require a smooth and rust-free surface finish. This machine works on a hanging system, where parts are suspended on a hanger in a Y-shape design, making it easy to blast multiple components at the same time. This ensures even cleaning and saves time during the production process.

Being one of the trusted Y Hanger Type Shot Blasting Machine Manufacturers, sfecindia uses advanced technology and durable materials to create machines that provide long-lasting performance. Our machines are designed to reduce manual work, lower maintenance costs, and improve overall production output. With the increasing demand for quality finishing and surface treatment, many industries prefer our machines because they offer consistent results and high blasting efficiency. The Y Hanger Shot Blasting Machine is not only efficient but also eco-friendly, as it minimizes dust and waste, making the working environment safe and clean.

Cleaning / Heat Scale and Rust Removal.

Batch Operation

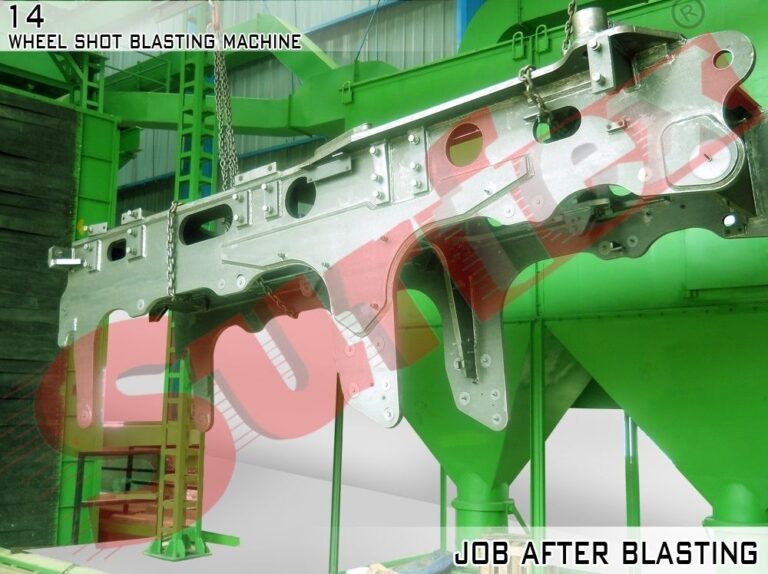

SURFEX® designs and manufactures the Y- Conveyor Type Spinner Hanger Shot Blasting Machine for a wide range of components (Castings / Fabricated / Forging / Aluminum Die Castings / Agriculture Components / etc.).

The machine consists of Total 2 No’s of Stations. The Trolleys (2 Set – one on each station) are mounted on the overhead Y- conveyor system to hold the jobs. The jobs to be shot blasted are loaded on these stations and one by one moved inside the blasting chamber for blasting purpose automatically. Suitable number of blast wheel stations are located (at one side of cabinet) strategically around the cabinet, which fires blasting abrasive media on the rotating job/ hanger that contain jobs. After the blast cleaning cycle is over, the blast wheel is shut off and trolley moves out automatically for unloading of component and the process is repeated.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.

Cleaning / Heat Scale Removal

Batch Operation

At sfecindia, we understand that every industry has different requirements, so we provide customized solutions for our clients. Whether you need a compact model for small components or a heavy-duty model for large castings, we have the right machine for you. Our team of experts designs machines that are easy to operate and require minimum training for workers. As one of the leading Y Hanger Type Shot Blasting Machine Manufacturers, we focus on providing machines that help industries save time, increase productivity, and achieve excellent surface finishing. By choosing sfecindia, you are assured of getting a machine that meets international quality standards and performs smoothly for years.

The Y Hanger Shot Blasting Machine is a perfect choice for businesses that want to achieve rust-free, paint-ready, and smooth surfaces on their metal products. It is widely used before painting, coating, or welding, ensuring that the finished product is strong and durable. The machine can handle both small and large batches of components, making it suitable for mass production industries. Its advanced design allows for continuous operation, which means industries can meet bulk orders without compromising on quality.

In today’s competitive market, having the right surface preparation machine is essential for maintaining product quality and customer satisfaction. The Y Hanger Type Shot Blasting Machine from sfecindia is the perfect solution for industries looking for reliability, efficiency, and cost-effectiveness. By investing in our machines, you can improve your production line, reduce downtime, and achieve superior results.

Cleaning / Heat Scale and Rust Removal.

Continuous Operation

SURFEX® designs and manufactures the Overhead Close Loop Conveyor Type Spinner Hanger Shot Blasting Machine (with Chain Conveyor) for a wide range of components (Castings / Fabricated / Forging / Aluminum Die Castings / Agriculture Components / etc.).

The machine consists of multiple sets (as required) of job conveying stations to hold the jobs. The jobs to be shot blasted are loaded on these stations and taken one by one inside the blasting chamber for blasting purpose automatically. Suitable numbers of blast wheel stations are located strategically around the cabinet, which fires blasting abrasive media on the rotating job/ hanger that contain jobs. After the blast cleaning cycle is over, the blast wheel is shut off and trolley moves out automatically for unloading of component and the process is repeated.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.

Cleaning / Heat Scale Removal

Continuous Operation

SURFEX® designs and manufactures the Overhead Close Loop Conveyor Type Pass Through Shot Blasting Machine (with Chain Conveyor) for a wide range of components (Castings / Fabricated / Forging / Aluminum Die Castings / Agriculture Components / etc.) and for Structural Cleaning.

The machine consists of multiple sets (as required) of job conveying stations to hold the jobs. The jobs to be shot blasted are loaded on these stations and taken one after another (with suitable gap) inside the blasting chamber (on continuous basis) for blasting purpose automatically. Suitable numbers of blast wheel stations (suitable number on one side and also on opposite side for continuous pass through shot blasting operation) are located strategically around the cabinet, which fires blasting abrasive media on the jobs. After the blast cycle is over, the job conveying station moves (with blasted job) out automatically for unloading of component and the process is repeated continuously.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.

Cleaning / Heat Scale and Rust Removal.

Continuous Operation

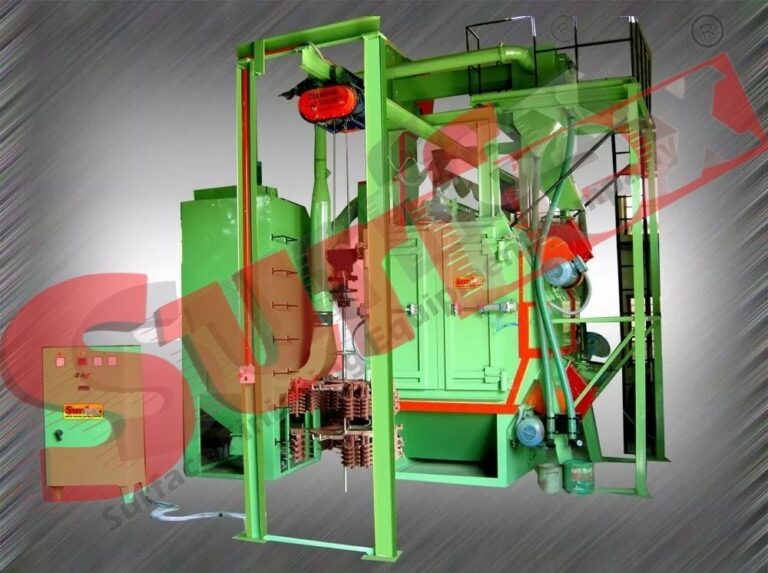

SURFEX® designs and manufactures the Indexing Hanger Type Shot Blasting Machine for a wide range of components (Castings / Forging / Aluminum Die Castings / etc.).

The machine consists of suitable number job stations (2 No’s / 4 No’s) with indexing hanger. The job is load (placed) manually on the job fixture (hangers) of the respective station of the main indexing turn table by the operator at the loading / un-loading station. Then the station (with loaded hanger) is indexed into the blasting chamber for shot blasting purpose. Suitable numbers of blast wheel stations are located strategically around the cabinet, which fires abrasives on the rotating jobs. After the blast cycle is over, the station (with blasted jobs) is indexed for unloading and simultaneously another station containing the new jobs index into the blasting chamber thus makes the process continuous.

When one station (with jobs) is under the blasting operation in blasting chamber, simultaneously at loading/ un-loading station the operator will un-load the blasted jobs and load the new jobs manually.

SURFEX® equipment includes a fully automatic Dust Collection System to remove dust and fines from the blast cabinet.